Blog

A few weeks ago, I had the pleasure of sitting down and speaking with a couple of gentlemen who collectively had more than 60 years’ experience in a global industry. In the early years of their business, they were able to use domestic suppliers for everything, but as competition in their space grew, prices were driven down, and they like many other original equipment manufacturers, found it necessary to source product components overseas.

Electronic Manufacturing Service (EMS) providers are often asked to do the impossible. In most cases “the impossible” refers to the delivery deadline. Industry veterans know what it takes to produce their products, and they consider the timeline challenges of their EMS when planning product launches and production runs. Those who do not, often find themselves wrestling with supply chain and product delivery issues.

Outsourcing electronics manufacturing and assembly can provide a wide range of benefits to companies who choose wisely. Not every project is a good fit for all manufacturers, but having an electronics manufacturer who brings more to the table than merely executing the prescribed instructions on a PO, should pay significant dividends.

A few weeks ago, I shared an article that explained the basics of conformal coatings. The article provided a brief description of the benefits of coatings, with the most obvious benefit being, they create a barrier between sensitive surface mount device and the environment in which they function. I also mentioned some additional protections they provide, such as protecting solder contacts from thermal and mechanical shock, and corrosion.

Solder paste is commonly used to create electrical connections and mechanical bonds between printed circuit board pads and surface mount devices, such as resistors and capacitors. It is made up of powdered solder in a flux paste. The flux serves several purposes. It removes oxidation from metallic surfaces, it protects the components to be soldered, as well as the metallic surface on the board.

Conformal coatings are simply coatings that are used to protect printed circuit boards. They form a barrier between the environment and the board and its’ electronic components, but the protections go far beyond that.

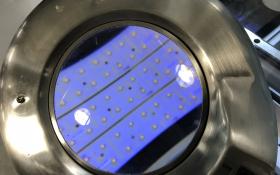

In 2016, Global Manufacturing Services added new high-speed pick & place equipment capable of placing up to 28,000 surface mount devices per hour. These pick and place machines are fast, but more importantly, they are very accurate. This new equipment is sandwiched between our automated stencil printing, and reflow equipment, increasing our production capabilities by more than 40%.